Fiber Optic Connector Types: Visual Identification Guide

Three weeks back, logistics company in Texas. Procurement manager calls in, says he needs "the blue fiber cables, the small ones." Standard request, right? Forty minutes later we're still screen-sharing photos because his maintenance tech photographed a green-booted LC/APC patch cord in backlight - looked blue on his phone screen - and called it up to purchasing. The PM had already clicked "add to cart" on 200 pieces of LC/UPC duplex. Wrong polish angle. Every single one incompatible with their PON equipment.

If that order ships and someone plugs them in, you're replacing connectors on both ends. Four grand minimum. Six hours downtime across two distribution hubs. And the tech who made the call? He's been doing fiber work for eight years. This wasn't incompetence. This was nobody teaching purchasing teams the visual coding system that connector designers spent thirty years perfecting.

The color codes are there. The mechanical differences are obvious once you know them. The problem is every supplier website shows you the same generic product grid with insertion loss specs and no purchasing intelligence. We're going to fix that.

Read a Fiber Connector in Five Seconds - No Framework Bullshit

When a patch cord hits your desk, you're looking at three things. Get any one wrong and you're either shipping it back or explaining to your network team why their new switch has blown transceiver ports.

Shape first.

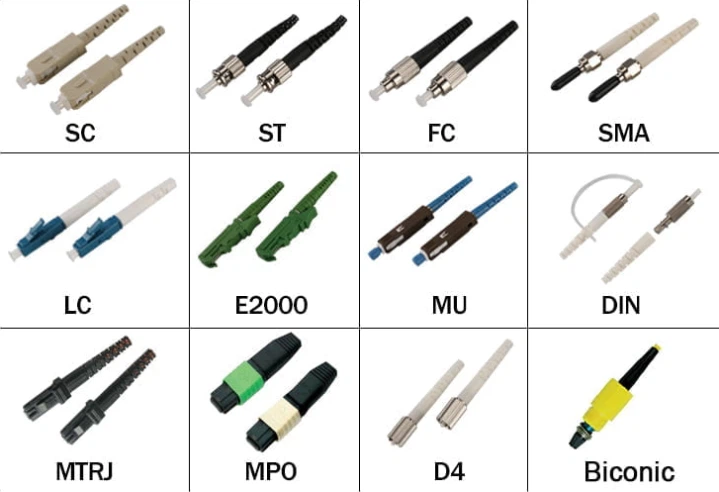

LC is small rectangular with a latch tab you press to release - that's your 1.25mm ferrule, fits every SFP form factor made in the last decade. SC is the bigger square body that clicks when it seats, pulls straight out. FC has metal threads you screw on. ST is round, push-and-twist bayonet like old BNC coax. MTP/MPO is the wide multi-fiber rectangle with guide pin holes visible on the face. Five shapes. Two seconds to ID.

Cable jacket color.

Yellow is single-mode. Orange is legacy multimode (OM1/OM2, probably installed 2005-2015). Aqua is modern multimode (OM3/OM4, your current data center short-reach standard). Lime green is OM5 wideband, still rare in the field. If you see purple or magenta, that's usually vendor-specific custom marking - verify with the supplier.

Connector body color - this is where money disappears.

Green means APC. Full stop. Not "usually APC" or "probably APC." Green is always 8-degree angled polish. Blue means single-mode UPC. Beige or aqua means multimode. If someone hands you a green connector and says it's UPC, they're wrong or lying. The green/blue distinction is an engineering mandate, not a suggestion, because mating APC into UPC destroys both ferrule end faces and kills 90% of your signal at the junction.

We've seen the damage. Customer in Phoenix mated one APC jumper into a UPC port on a Cisco ASR. Insertion loss spiked to 11.2 dB on that link. That's not "degraded performance." That's a dead optical path. Both connectors went in the trash, plus the adapter had to be replaced because the ferrule scraped ceramic dust into the alignment sleeve. Two-hundred-dollar mistake on a $12 patch cord.

LC: Stock This or Stock Nothing

Every transceiver your network team orders - SFP, SFP+, SFP28, QSFP28, doesn't matter - uses LC ports. We track our own order data. When someone sends an RFQ for "fiber patch cords" without specifying connector type, it's LC duplex 87 times out of 100.

Here's why LC pricing is all over the map: Lucent held the patents for years. Licensing fees kept costs artificially inflated. Those patents expired 2018-2019. Now you've got dozens of manufacturers cranking out spec-compliant LC connectors with no royalty overhead. If a supplier quotes you premium pricing "because of the LC technology," they're running 2015 price sheets or they're padding margin. Walk.

What you should pay (2025 pricing):

- LC/UPC simplex, single-mode, 3-meter: $2.40-$3.80 at 500-qty

- LC/UPC duplex, single-mode, 5-meter: $4.20-$6.50 at 500-qty

- LC/APC duplex, single-mode, custom length: Quote us - lead time 3-5 days

We ship LC assemblies with per-connector test data. Insertion loss, return loss, end-face geometry measured and printed on the report that goes in the box. If your current supplier gives you a certificate of conformance without actual measurement data, ask them why. Then call us.

SC: The FTTH Workhorse (And Why It's Not Going Away)

Bigger square body. 2.5mm ferrule. Push-pull coupling with a satisfying click when it seats properly. SC dominates fiber-to-the-home, GPON/EPON equipment, outside plant distribution. If your business touches broadband delivery, SC is 40-60% of your connector BOM.

SC pricing is stable because there's no patent legacy inflating costs. Expect $3-$5 per duplex assembly at volume, depending on cable grade and length. We stock SC/UPC and SC/APC in single-mode, OM3, and OM4 configurations. Custom lengths ship in 3 business days.

The click matters more than people think. That audible snap is tactile confirmation of full engagement. We've debugged customer sites where intermittent link errors traced back to SC connectors that weren't fully seated - they looked connected, but the latch hadn't engaged. No click, no connection. Train your install teams to listen for it.

FC: Dying Slow, But Still Billing Hours

Threaded screw-on coupling. Metal barrel. You'll find FC on OTDRs, optical power meters, lab test equipment. New installs rarely specify FC anymore, but if you're supporting brownfield infrastructure with test gear from 2010-2020, you're stuck with it.

Here's the trap nobody warns you about: FC/APC comes in two incompatible key widths. The "reduced" key is 2mm. The NTT standard key is 2.14mm. Look for scribe marks on the connector barrel - single mark means reduced, double marks means NTT.

Order the wrong one and the connector physically seats in the adapter but the angular alignment is off by 0.14mm. The link works. Return loss is degraded. You get intermittent bit errors that look like dirty connectors or bad fiber. Troubleshooting takes hours because nothing is visibly wrong.

Last year we processed a return from a university research lab. Fifty FC/APC reduced-key assemblies. Their entire test bench uses NTT-key adapters. Every connector seated. Every measurement was garbage. Took them a week to figure out they had a key mismatch. Took us three days to remake the order with correct keys and ship it back.

Sourcing FC assemblies: Specify the key width in your PO. Don't assume. Send us a photo of your existing equipment if you're unsure - we'll verify key type before we build anything.

ST: Legacy Infrastructure Tax

Push-and-twist bayonet. Looks like BNC from the coax era because AT&T based the design on it. Campus LANs in the 1990s ran on ST. Most of that infrastructure is still operational in government buildings, universities, manufacturing plants that haven't refreshed in 15-20 years.

If you're quoting replacement cords for a brownfield site, confirm ST vs SC before you order. They're similar size. Completely incompatible coupling. We get calls every month from buyers who ordered SC because "it looked the same in the photo."

ST is maintenance mode. We stock it. We'll build custom assemblies if you need them. But if you're designing new infrastructure, don't specify ST. You're buying into an orphaned connector family with shrinking supplier support.

MTP/MPO: The Backbone Connector Nobody Explains Properly

Rectangular multi-fiber ferrule. 8, 12, 16, or 24 fibers in one connector. This is your 40G/100G/400G backbone standard. If you're running data center spine-leaf architecture or AI/ML training clusters, you're buying MPO in volume.

Here's the purchasing decision that actually matters:

MPO is the generic IEC/TIA standard. MTP is US Conec's proprietary tighter-tolerance variant. They physically intermate, but there's a real quality and durability gap:

| Spec | Standard MPO | MTP (US Conec) | FOCC MTP-Compatible Premium |

|---|---|---|---|

| Unit cost | ~$1.40/connector | ~$6.35/connector | ~$4.80/connector* |

| Rated cycles | 200 | 500+ | 500+ |

| Per-cable premium vs baseline | - | +$12-15 | +$8-10 |

| Use case | Non-critical distribution | 400G backbone trunks | High-density backbone, budget-conscious |

| Lead time (stock config) | 7-10 days | 10-14 days | 3-5 days |

*Volume pricing available at 50+ assemblies. MTP is a US Conec trademark; our assemblies meet equivalent mechanical tolerances.

For 400G trunks in production, the MTP premium is money well spent. For distribution patches where you're not pushing link budget limits, standard MPO works fine. We can walk through which applications justify which grade - that's a real conversation, not a sales pitch, because specifying the wrong one costs you later.

The gender trap that costs service calls:

MTP/MPO connectors are gendered. Male has guide pins sticking out. Female has guide holes. Mate two males and the pins ram into a flat surface. Both connectors destroyed instantly.

We had a customer receive a shipment of 120 MPO-12 assemblies - 60 male, 60 female - packed in generic boxes with no gender marking. Warehouse staff binned them together because "they're all 12-fiber MPO." Install crew got to the site, started pulling random cables, mated male-to-male on the third attempt. Destroyed both connectors. Spent two hours sorting the remaining 118 assemblies by gender using a flashlight and magnifying glass.

We now ship MPO assemblies with color-coded labels: blue for male, red for female. It's not a standard. It's common sense that should've been common practice a decade ago.

Polishing Types: The 10 dB Difference Between Working and Broken

| Polish | Return Loss | Light Reflected | What It's For |

|---|---|---|---|

| PC | ~-40 dB | 0.01% | Legacy telecom (being phased out) |

| UPC | -50 to -55 dB | 0.001% | Data center Ethernet, enterprise IT |

| APC | -60 to -65 dB | 0.0001% | CATV, FTTH, DWDM, anything analog |

The 10 dB gap between UPC and APC isn't academic. In analog CATV distribution, reflected light bouncing back to the source creates visible interference in the video signal. At -40 dB (PC polish), you see noise in the picture. At -65 dB (APC), reflected power is below the noise floor.

For digital Ethernet, UPC is fine. For anything wavelength-multiplexed or carrying analog signals, APC is a technical requirement.

We get requests to "just use APC everywhere for safety." Sounds smart. Doesn't work. APC connectors cost 15-25% more to manufacture because holding tolerance on the 8-degree angle is harder. And most switch/router ports ship with UPC adapters. Plug APC into a UPC port and you destroy both surfaces.

Better approach: Match your connector polish to your equipment ports. Train your team to respect the green/blue color code. Keep APC and UPC in separate inventory bins. Label them. We've seen too many "mixed polishing type" RMAs that could've been prevented with a $4 label maker.

Budget Connectors vs. Quality: The $80K Lesson

Food processing plant. Minnesota. 2024. Someone on their maintenance team mated an APC connector into a UPC port on a production line inspection camera link. The camera went offline. Line stopped. Forty-five minutes of downtime.

Total cost: $82,000 in lost production, plus $1,800 to replace the damaged connectors and adapter panel.

Savings from buying budget patch cords that quarter: $1,150.

Industry surveys publish these "$14,056 per minute" downtime averages, and every purchasing manager reads them and thinks "that's not us, we're not a hyperscale data center." Then it happens. One contaminated connector takes down your ERP database link and accounting can't process invoices for three hours.

Here's what separates budget from premium at the manufacturing level:

Budget connectors use generic 127-128µm ferrule bores for 125µm fiber. They center the fiber with epoxy and hope. Premium manufacturers - Corning, TE, us - batch-match ferrule bores to actual fiber outer diameter. Your fiber measures 124.7µm? We pull ferrule stock that's 125.0µm bore. That's 0.3µm clearance, mechanically centered.

Budget approach gives you concentricity errors above 1.6µm. Premium holds 0.3-0.5µm. That shows up as insertion loss variation: budget averaging 0.3-0.4 dB per connector, premium under 0.12 dB. Multiply across 10-15 connection points in a link path and you've burned half your optical budget on manufacturing slop.

Mating durability: premium connectors maintain spec through 1,000+ insertions. Budget connectors rated for 200 cycles start degrading return loss around cycle 150 if the polish wasn't done to IEC 61300-3-47 standards. Patch panel gets reconfigured weekly? You're replacing budget connectors in under four years.

FOCC quality controls:

- Interferometric end-face inspection (every connector, not sample-based)

- Cpk >1.33 on insertion loss across production lots (ask us for the data)

- Per-assembly test reports included in shipment

- 1000+ cycle rating on our premium line

We're not the cheapest. We're also not explaining to your CFO why a $3 patch cord caused $80K in downtime.

Pre-Terminated vs Field: The ROI Math Your Integrator Won't Show You

Field termination looks cheaper on the quote. It's not cheaper when you account for labor, rework, and time-to-operational.

| Cost Element | Field (per 100 links) | Pre-Terminated (per 100 links) | FOCC Pre-Term Pricing |

|---|---|---|---|

| Skilled labor | 50-80 hrs @ $75-120/hr avg | 10-15 hrs @ $45-70/hr | Same install labor |

| First-pass cert rate | 43% (Fluke 2023 data) | 95%+ factory tested | 98.2% (Q1 2025 data) |

| Rework cycles | 15-25 hours typical | Warranty replacement | We overnight replacements |

| Time to operational | 5-12 days | 1-2 days | Stock configs: same-day ship |

| Total cost (typical) | Higher + schedule risk | Lower + predictable | Quote within 4 hours |

The first-pass certification rate is the killer. Fluke found 57% of field installs fail testing on first attempt. That's more than half your connections needing rework. Every rework cycle adds labor, delays go-live, and introduces new contamination risk.

Pre-terminated from quality manufacturers ships with test data for every single connector. Measured in controlled environment. No field variables. No "tech having a bad day" risk.

500-port data center example: Field termination saves maybe $3K on materials. Adds $18K-35K in skilled labor, tool costs, and rework. Pre-terminated has higher material cost but cuts deployment from 8 days to 2 days, uses lower-skill labor for installation, comes with factory certification.

Most ops break even on pre-term premium within the first deployment.

FOCC pre-terminated capabilities:

- Any connector combination in this guide

- Custom lengths (no standard increment restrictions)

- 3-5 day lead time for stock configurations

- Volume pricing at 50+ assemblies

- We handle weird requests (hybrid polishing, custom jacket colors, non-standard polarity)

Send us your BOM. We'll have pricing back to you in 4 business hours. If your current supplier takes 48+ hours to quote custom assemblies, that's your sign to call us.

400G/800G: The Connector Shortage Nobody's Talking About Yet

AI buildouts are eating fiber. We're seeing RFQs for MPO-16 and MMC-16 assemblies from customers who six months ago were asking "what's the difference between MTP and MPO."

Nvidia's new Blackwell GPU nodes use 16x more fiber per rack than traditional cloud servers. Sixteen times. Not a typo. Every AI training cluster deployment is pulling forward 2-3 years of connector demand into a 6-month window.

Very Small Form Factor (VSFF) connectors are here whether you're ready or not:

- CS connector (SENKO/Sumitomo): 2x LC density, QSFP-DD/OSFP form factors

- SN connector: 3x LC density, targeting 800G and 1.6T

- MMC-16: 3x MPO density for 800G parallel optics

These are physically smaller than LC. CS duplex looks like LC simplex if you don't know the form factor. First time your warehouse receives them without reference photos, someone's going to mis-bin them.

Supply chain reality check: Lead times on pre-terminated 24-fiber MPO trunks have stretched from 3 weeks to 7-9 weeks industry-wide. Everyone's scrambling. Manufacturers who planned capacity around steady 10-15% annual growth are facing 40-60% spikes in orders from hyperscale and AI infrastructure buyers.

If you're supporting any AI/ML deployment, any 400G+ backbone refresh, build MPO/MTP into your forecasting now. Don't wait for the RFQ to land.

FOCC's current capacity:

- MMC-16 assemblies: in production, 5-7 day lead time

- MPO-24 trunks: stock Type A polarity, 3-5 days for custom polarity

- CS and SN: sample quantities available, volume production Q2 2025

- We're one of the few mid-tier manufacturers already shipping VSFF configs

Receiving Inspection: 90 Seconds That Prevents Returns

Run this sequence before anything enters inventory. This is the exact process our QC staff uses.

Step 1:

Mechanical ID (5 seconds)

Pick up connector. Threaded barrel = FC. Bayonet twist = ST. Small rectangular latch tab = LC. Bigger rectangular push-pull = SC. Wide multi-fiber = MTP/MPO. Spring shutter = E2000.

Step 2:

Color verification (10 seconds)

Blue connector + yellow cable = single-mode UPC. Green connector + yellow cable = single-mode APC. Aqua connector + aqua cable = OM3/OM4. Mismatch = hold for engineering review. Hybrid patch cords exist, but verify against PO before binning.

Step 3:

MPO gender check (15 seconds, MPO only)

Look at connector face. See pins sticking out = male. See holes = female. Confirm against order spec. Check polarity marking if specified (Type A/B/C). Wrong gender = complete link failure. Wrong polarity = same.

Step 4:

End-face inspection (60 seconds)

Every connector. Not just the ones that look dirty. Use proper fiber scope or inspection tool. Contamination is responsible for 85% of fiber link failures (BICSI field data). Don't use IPA from the hardware store - wrong grade leaves residue halos. Use reagent-grade IPA or dry cleaning cassettes.

Inspect. Clean. Inspect again. A cleaning pass that redistributes contamination instead of removing it will pass visual inspection but fail under magnification.

What we ship:

- Individual optical test reports (insertion loss, return loss, geometry)

- End-face inspection photos for MPO assemblies (on request)

- Color-coded gender labels for MPO (blue = male, red = female)

- Certificate of conformance with actual measurement data, not just "meets spec"

If your current supplier doesn't provide per-connector test data, ask why. If the answer is anything other than "here's the test report," find a new supplier.

Work With FOCC: Fast Quotes, Faster Delivery, No Runaround

We manufacture in Shenzhen. Monthly capacity over 1.5 million connectors across three facilities. Every connector type in this guide, plus the emerging VSFF formats.

What we're good at:

- Custom assemblies (length, polishing, jacket color, hybrid configs)

- Fast quotes (4-hour turnaround on standard RFQs)

- Short lead times (3-5 days for stock configs, 7-10 for custom)

- Volume pricing that doesn't require a Master Service Agreement and three months of negotiation

- Handling weird requests (we've built stranger things than you're about to ask for)

What we're not good at:

- Sitting on quotes for 48 hours because "that's our process"

- Telling you "minimum 1000 pieces" when you need 50 for a pilot

- Shipping COC documents with no actual test data

- Making you talk to three people before you get pricing

How to get a quote:

Email your BOM to focc@focc-fiber.com.

Include connector types, lengths, quantities, and timeline. We'll have pricing back in 4 hours during business hours (GMT+8).

For immediate questions, call +86-138-2323-7984.

If anything in this guide raised questions about your current specs or upcoming deployment, our engineering team does complimentary connector ID and link budget consultation. No sales pitch. Just an actual engineer who's built this stuff walking through what you need.

FOCC Fiber Co., Ltd. | Shenzhen, China | www.focc-fiber.com

References: TIA-598-C, IEC 61755, IEC 61300-3-35. Market data from Grand View Research, EMA 2024, ITIC 2024, Fluke Networks 2023. ROI calculations are representative examples; verify against your specific project parameters.